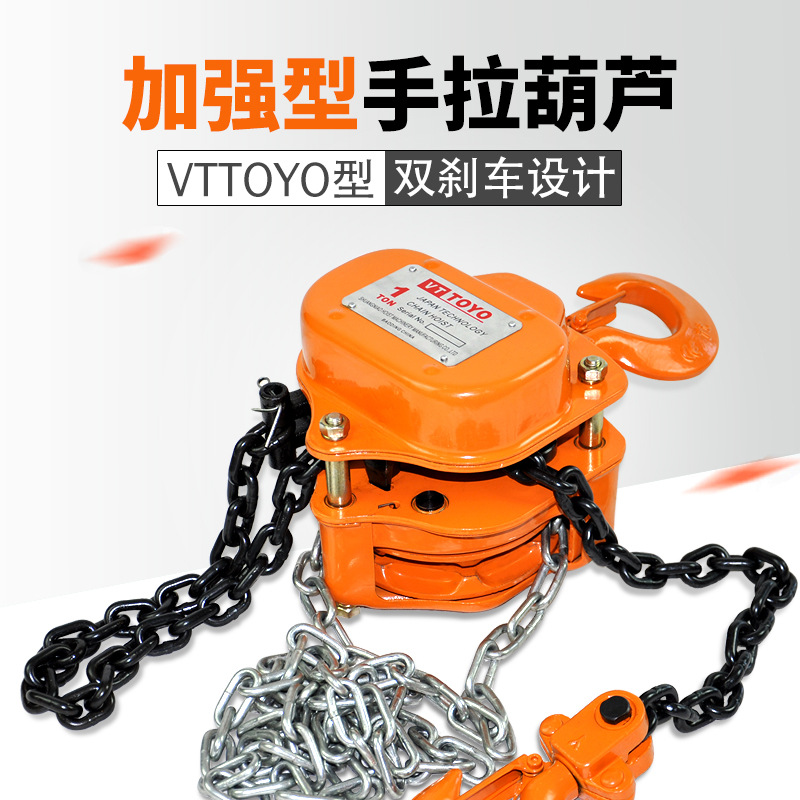

Reshaping Work Efficiency-Analyzing How VTTOYO Manual Hoist Helps Industrial Handling Upgrade

In heavy industrial working environments, a reliable manual hoist can not only improve efficiency, but also significantly reduce operational risks. VTTOYO manual hoist with its high strength alloy chain and precision mechanical structure design, has become the first choice for many professional users. Whether it is the transfer of parts in the daily production process or the stacking management of goods in the storage environment, it can quickly respond to task requirements and greatly reduce the burden of manpower.

Comprehensive Analysis from Material to Performance -- Revealing the Core Advantages of VTTOYO Manual Hoist

Different from ordinary lifting equipment, VTTOYO uses advanced tensile alloy materials to make chains, coupled with a tightly engaged gear system, to ensure that each lifting is smooth without shaking. At the same time, the shell treated with a special anti-rust coating shows excellent stability in wet or dusty environments. The whole device runs quietly and smoothly, and there will be no obvious signs of wear even if it is operated continuously for high frequency times.

Humanized Design Concept Blessing-Make Complex Tasks Simple and Controllable

taking into account the user's operating habits and comfort, VTTOYO manual hoist specially optimizes the angle of the hand chain and the sensitivity of the braking system to achieve the goal of easy control of heavy objects by a single person. Whether it is overhead shelf finishing or large component assembly, it can meet the challenge with ease. The innovative dual-mode locking mechanism can be fixed immediately at any height to prevent potential safety hazards caused by accidental touch.

Wide Scope of Application-Live Analysis of Multi-industry Application Scenarios

this powerful manual hoist is not only active in material transfer in various manufacturing plants, but also suitable for loading and unloading goods in logistics centers or assisting in the installation of auxiliary facilities such as scaffolding on the construction site, thus saving cost input in a real sense. The flexible length adjustment design enables it to meet the lifting requirements of different floors, thus reducing the repeated purchase expenses.

ROI Analysis-Why VTTOYO over Other Brands

Although the initial purchase price may be slightly higher than the market average, the average annual expenditure required in the long run is lower due to excellent quality control standards and long maintenance cycle settings. More importantly, the security and sustained productivity it brings are far more than numbers can measure. Each machine undergoes rigorous stress testing before leaving the factory to ensure that it is in the best state of plug and play when delivered to customers.