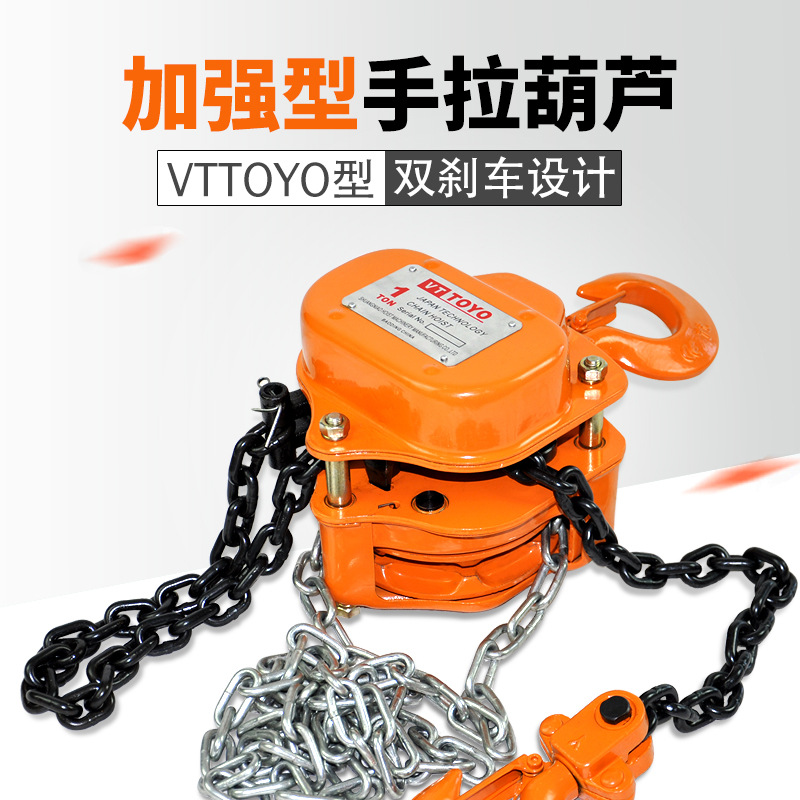

Whether it's a busy factory floor or an orderly construction site, you can always see a small but powerful tool shuttling around every corner-the acclaimed manual chain hoist. Among them, the VTTOYO brand is the representative, which has won the high recognition of the market with its excellent performance and reliable quality.

Facing the lifting needs of daily work, a manual chain hoist with a rated load of 2 tons and a chain length of 3 meters is undoubtedly one of the most ideal choices. It can not only meet the load-bearing requirements in most scenarios, but also benefit from the simple and intuitive operation process, even novices can quickly get started. For example, in a large warehouse renovation project, the construction team used this equipment to complete a large number of cargo handling tasks, which greatly improved work efficiency.

Such outstanding performance is inseparable from VTTOYO's consistent pursuit of product quality. Each hoist uses a high-strength chain made by precision forging process to ensure stable operation even in harsh environments. The ergonomically designed handle makes the operation more labor-saving and comfortable. In addition, the special anti-corrosion coating protects the shell from external invasion, all of which together constitute an ideal tool that is both durable and safe.

In order to better realize the potential of this product, please be sure to pay attention to some practical tips. First of all, the correct installation position selection, must ensure that the lifting point is firm and away from the personnel activity area; Secondly, carefully check whether the load is evenly distributed before each operation to avoid accidents caused by the deviation of the center of gravity. Finally, don't forget to regularly clean and maintain the oil and dust on the surface of each component, which can not only prolong the service life but also ensure the safety of long-term use.

The positive feedback from countless customers fully confirms the value of VTTOYO manual chain hoist. "Since the introduction of this equipment, our production cycle has been significantly shortened and labor input costs have been significantly reduced." A person in charge of manufacturing enterprises said. Not only that, there are many small and medium-sized enterprises have also benefited a lot from it, and gradually realized the goal of transforming from traditional manpower to modern machinery.

With the changing market demand and accelerating technological progress, the future of manual lifting equipment will usher in a new period of development opportunities. On the one hand, the lightweight design concept will be adopted and implemented by more and more manufacturers, aiming to reduce the weight of the whole machine without affecting the original functional indicators; On the other hand, the intelligent control system is expected to become the standard option, allowing remote monitoring parameter setting and even predicting potential failure risks, making the whole process more transparent and controllable.